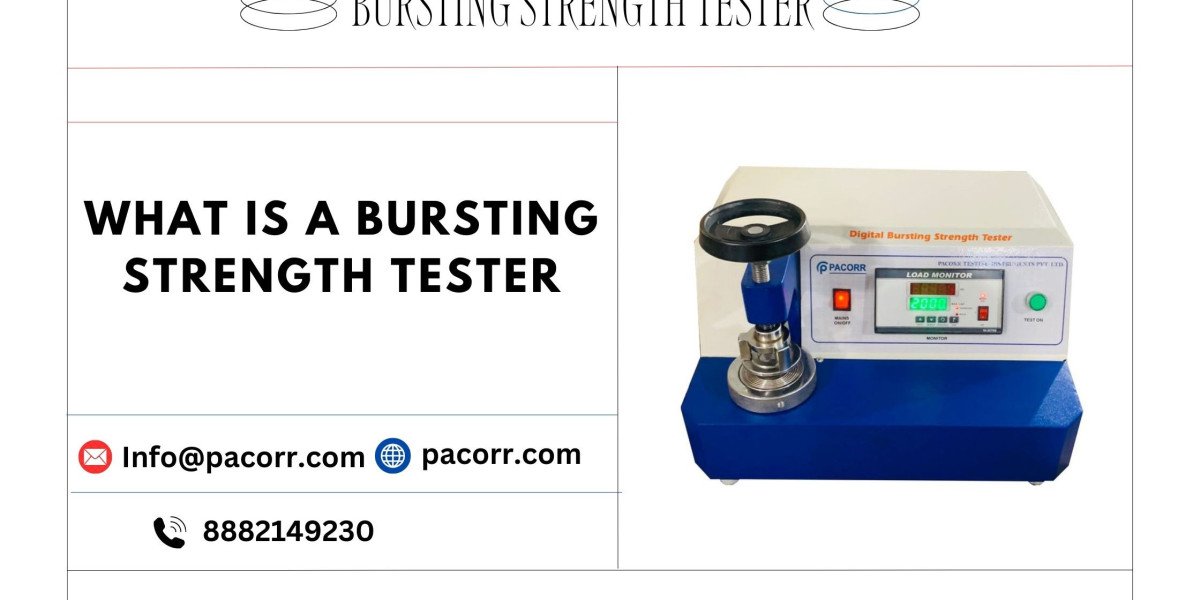

What is a Bursting Strength Tester?

A bursting strength tester measures the ability of a material to withstand pressure until it bursts. By applying a uniform force to a sample, the tester determines how much pressure the material can handle before breaking. This provides manufacturers with valuable data to evaluate the strength and reliability of their products.

Whether testing paper, cardboard, fabric, or flexible films, the bursting strength tester ensures materials meet quality standards and are fit for their intended use.

Why is Bursting Strength Testing Important?

Bursting Strenght Testing is essential for assessing the quality of materials that face pressure or stress during their lifecycle. Weak materials can fail during use, leading to product damage, customer dissatisfaction, or even safety hazards. By testing bursting strength, manufacturers can:

- Ensure product durability.

- Identify weaknesses early in production.

- Meet industry and regulatory standards.

- Improve customer trust and satisfaction.

Industries that Use Bursting Strength Testers

Bursting strength testers are used in various industries, including:

- Packaging and Shipping

- Ensures corrugated boxes, cartons, and paper bags can handle stacking, transportation, and handling.

- Evaluates food-grade packaging for strength and safety.

- Paper and Pulp Industry

- Tests the strength of paper sheets, boards, and recycled paper materials.

- Verifies that products meet international standards for packaging and printing.

- Textile Manufacturing

- Assesses the tensile strength of fabrics for clothing, upholstery, and industrial applications.

- Ensures fabrics meet performance and durability expectations.

- Plastics and Flexible Materials

- Tests films, rubber sheets, and other flexible materials for their ability to handle stress.

- Helps manufacturers ensure consistent quality in industrial and packaging applications.

Benefits of Using a Bursting Strength Tester

Incorporating a Bursting Strength Tester Price into your quality control process offers several advantages:

- Improved Product Quality: Regular testing ensures only strong, reliable materials are used in production.

- Reduced Waste: Identifying weak materials early reduces production losses and waste.

- Compliance with Standards: Ensures your products meet global quality and safety standards, such as ISO and ASTM.

- Enhanced Customer Satisfaction: Durable products lead to fewer complaints and higher trust.

- Cost Savings: Prevents costly recalls or failures by detecting issues before products reach the market.

Features of Advanced Bursting Strength Testers

Modern bursting strength testers are equipped with advanced features to provide precise, reliable results. Key features include:

- Digital Displays: Allow for accurate and easy-to-read test results.

- Wide Compatibility: Can test various materials, including paper, textiles, and films.

- Durable Construction: Built to withstand rigorous industrial use.

- Automated Functions: Enable consistent testing and save time.

How to Choose the Right Bursting Strength Tester

When selecting a bursting strength tester, consider the following factors:

- Type of Material: Choose a tester compatible with your specific material (e.g., paper, fabric, plastic).

- Pressure Range: Ensure the device meets the pressure requirements of your testing needs.

- Ease of Use: Look for features like automation and digital controls for simplicity.

- Industry Standards: Verify that the tester complies with relevant standards like ISO or ASTM.

Why Choose pacorr.com for Bursting Strength Testers?

At pacorr.com, we specialize in providing high-quality testing equipment tailored to diverse industrial needs. Here’s why businesses trust us:

- Top-Quality Products: Our bursting strength testers are designed for accuracy, durability, and ease of use.

- Expert Advice: Our team helps you select the right model for your specific requirements.

- Reliable Support: We offer full support, from installation to maintenance, ensuring seamless operation.

- Custom Solutions: We tailor testing solutions to meet your unique business needs.

Final Thoughts on Bursting Strength Tester

A bursting strength tester is an indispensable tool for any industry that values quality and reliability. By ensuring materials meet Burst Strength Tester requirements, manufacturers can deliver products that perform well in real-world conditions, reduce waste, and maintain customer satisfaction.