BK Control Transformer Factory selection plays an important role in ensuring voltage regulation, signal clarity, and equipment protection in automated and industrial systems. For procurement teams, understanding the purpose and specifications of BK transformers is essential before sourcing from a manufacturer.

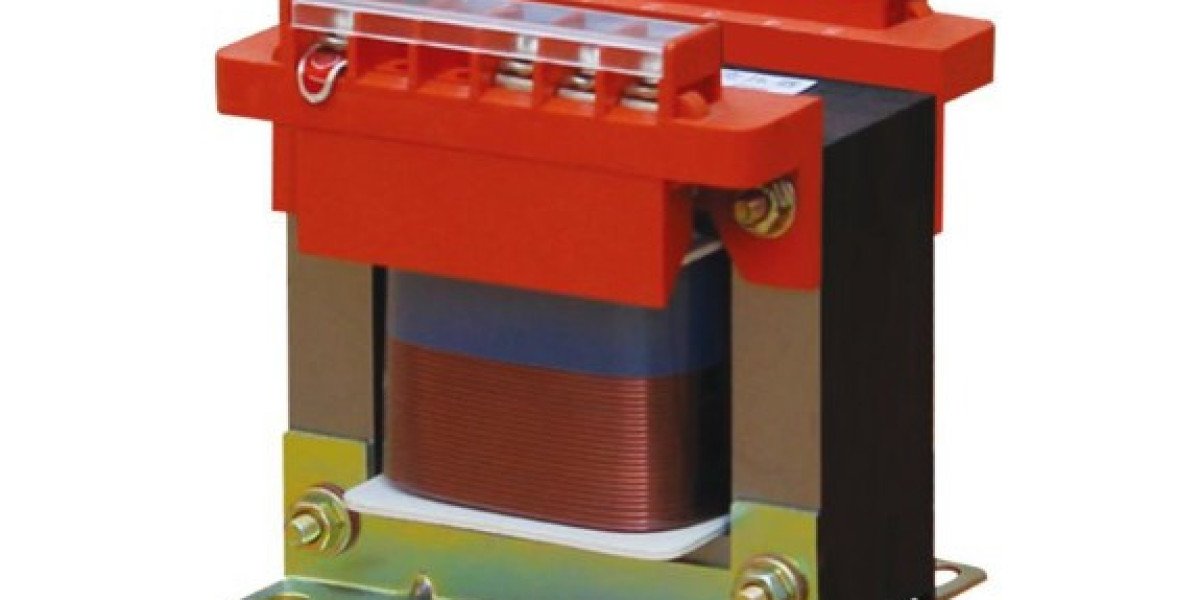

Control transformers, often referred to as BK types, are specifically designed to supply stable voltage to control circuits in machines and electrical panels. Unlike standard power transformers, they are built for short-time loads, focused voltage isolation, and reduced interference. In operations where consistent signal delivery is necessary, these transformers contribute to the overall reliability of the control system.

When sourcing BK transformers, buyers should consider the application environment. Is the system exposed to fluctuating loads, high humidity, or temperature changes? The material quality and insulation performance need to match these working conditions. A factory like Nbcbdz addresses these challenges by manufacturing units with durable core structures and high-temperature windings that remain stable over prolonged cycles.

One of the common concerns in industrial applications is whether the control voltage stays within the required range. Voltage drops or spikes can result in signal delay or controller failure. BK transformers reduce this risk by ensuring the control loop remains isolated from the power side, maintaining a clean signal.

In addition to technical specs, ease of installation and layout also influence selection. The factory offers multiple configurations that support various mounting types, including base-mounted or panel-installed units. This reduces downtime during setup and simplifies future replacements.

For custom systems, transformer ratings must align with the control load. Over-specification can cause unnecessary heat, while underspecification leads to failure under demand. Nbcbdz provides engineering support to help match transformer parameters to system needs, ensuring long-term functionality without unnecessary component stress.

Safety standards are another aspect to evaluate. Whether the transformer is used in automation equipment, CNC machines, or building management systems, compliance with regional certifications ensures reliable performance. Manufacturers with dedicated testing processes, like Nbcbdz, allow customers to source with confidence across sectors.

Operational continuity also depends on consistent sourcing. Partnering with a factory that delivers consistent quality and manageable lead times can prevent delays in broader equipment production. With scalable production capabilities, the factory helps small and large clients maintain supply chain flexibility.

BK transformers continue to be widely adopted because of their role in providing clean, regulated voltage to sensitive control points. As electrical systems grow more complex, stable control circuits become increasingly important. Whether for industrial, commercial, or infrastructure projects, selecting the right transformer improves output accuracy and supports system safety.

To begin sourcing control transformers suited for your application, visit https://www.nbcbdz.com/ and review available models and services.