The effectiveness of anionic polyacrylamide emulsion in various industrial processes is largely due to its unique chemical structure and behavior in aqueous environments. This emulsion consists of negatively charged polymer chains that interact selectively with suspended particles, promoting aggregation and improving processes like water purification and paper production.

Chemical Features That Drive Performance

| Feature | Description |

|---|---|

| Anionic Charge Density | Determines the attraction strength to positively charged impurities. |

| Molecular Weight Range | Affects polymer chain length, impacting viscosity and floc formation. |

| Emulsion Stability | Ensures even dispersion and prevents premature polymer aggregation. |

| Hydrophilic Properties | Facilitates interaction with water and suspended solids for better flocculation. |

These characteristics enable the polymer to act as a powerful flocculant, helping to clear water or improve fiber bonding in papermaking.

What Makes Emulsion Form Preferable Over Powder?

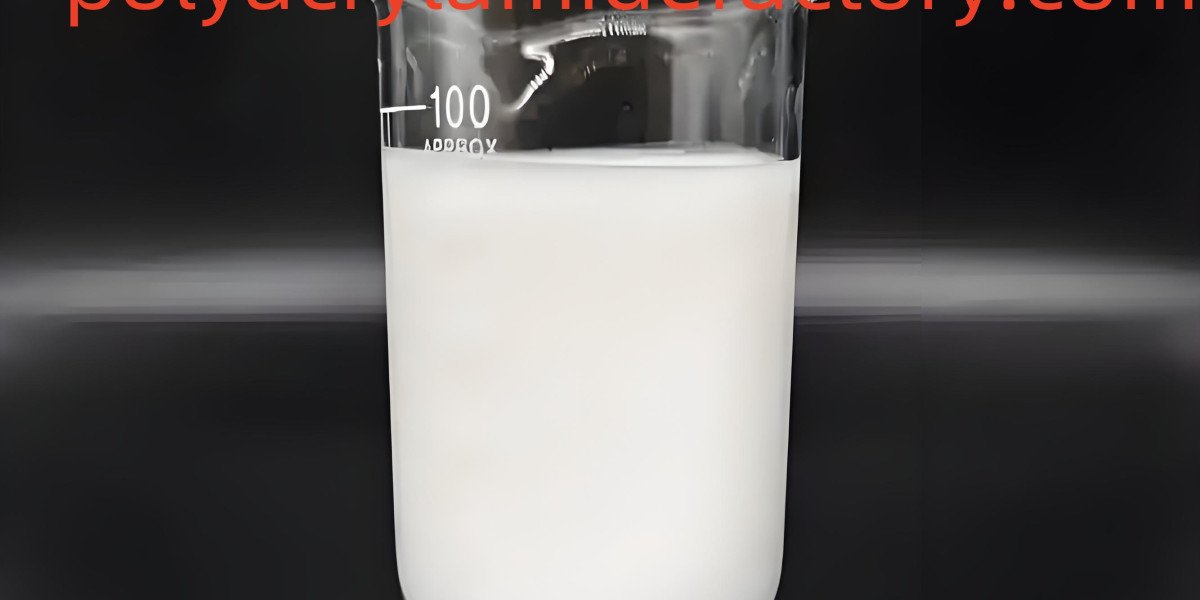

The emulsion form offers safer handling by reducing dust and enhancing ease of mixing into systems. It also provides improved storage stability and controlled polymer release, contributing to consistent performance in industrial applications.

Why Partner with Polyacrylamidefactory?

Polyacrylamidefactory specializes in producing top-tier anionic polyacrylamide emulsion solutions backed by stringent quality control. Our emulsions are designed for maximum efficiency, environmental compliance, and ease of use. Let us help you optimize your industrial processes with our reliable products and expert support.

Visit for more info:

https://www.Polyacrylamidefactory.com/news/industry-news/how-does-hengfeng-anionic-polyacrylamide-emulsion-work.html