The enduring appeal of a well-bound book remains undeniable, even in our digital age. Yet, the craft of binding is far from static. The once labor-intensive and often rigid realm of bookbinding is being redefined by advancements in automation, artificial intelligence, and a growing demand for personalized, sustainable solutions. This evolution promises unprecedented flexibility and precision for publishers, printers, and creators alike.

A Look Back: How Books Were Bound Before

For centuries, bookbinding was an intricate, highly skilled craft, predominantly executed by hand.

Before the industrial revolution, monks, scribes, and dedicated artisans meticulously stitched individual pages or folded sheets (signatures) together using linen thread. These sewn book blocks were then often secured with cords or tapes, which were laced through holes in wooden boards that formed the covers. These boards would then be covered with leather, vellum, or cloth, often decorated with intricate tooling, gold leaf, or embossing. This method, known as case binding (or hardcover binding), was incredibly durable but time-consuming and expensive.

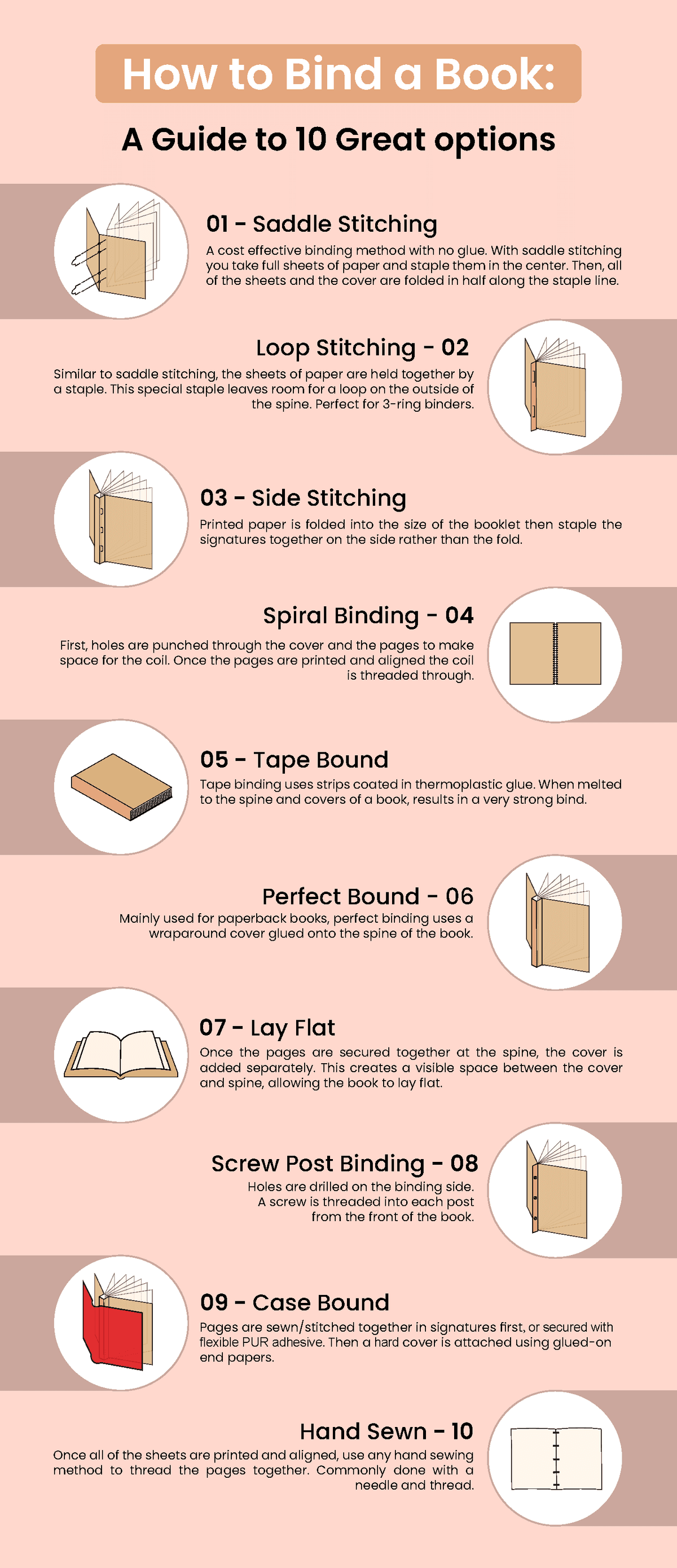

The invention of the printing press in the 15th century increased the demand for books, leading to more workshops but still relying heavily on manual labor for binding. Later, the 19th century brought steam-powered machinery that automated some processes like folding and pressing, but the core assembly and covering remained largely manual until well into the 20th century. The methods on how to bind a book were robust, built for longevity, and celebrated craftsmanship, but they simply couldn't keep pace with the scale and speed demanded by modern publishing.

The Driving Forces: Why Bookbinding is Evolving

Several key factors are accelerating technological advancements in bookbinding:

The Rise of On-Demand Printing: Digital printing has shifted the paradigm from large, speculative print runs to shorter, customized editions, even single-book production. This demands binding solutions capable of rapid changeovers and diverse formats with minimal downtime.

Demand for Customization: Consumers expect tailored products, from personalized covers to unique finishes. Bookbinding technology is adapting to enable variable data printing (VDP) directly onto covers and spines, offering bespoke aesthetics efficiently.

Efficiency and Cost Reduction: In a competitive market, optimizing operational costs while maintaining quality is crucial. Automation and smart technologies minimize human error, optimize material usage, and accelerate production cycles.

Sustainability Imperatives: Environmental consciousness is paramount. The industry is actively seeking greener glues, recycled materials, energy-efficient machinery, and processes that reduce waste.

Labor Challenges: Automation and AI-driven systems help bridge skill gaps and address labor shortages by simplifying complex operations and reducing the need for extensive manual intervention.

4 Key Technological Trends Shaping Bookbinding

The future of book binding is a dynamic interplay of several innovative technologies:

1. Advanced Automation and Robotics

Modern binding machines are increasingly sophisticated, handling complex tasks with impressive speed and precision:

Integrated Workflows: Systems now seamlessly connect digital prepress, printing, binding, and trimming into highly automated workflows. This "lights out" production minimizes human touchpoints, reducing errors and accelerating turnaround times.

Robotic Material Handling: Robots are deployed for tasks like signature gathering, precise cutting, stacking, and packaging, offering consistency and continuous operation.

Automatic Setup: Machines detect paper alignment and thickness, and can even read QR codes to instantly adjust settings for different job specifications, dramatically reducing make-ready times crucial for short runs.

2. The Role of Artificial Intelligence (AI) and Machine Learning

AI is subtly but powerfully revolutionizing print finishing:

Predictive Maintenance: AI analyzes machine performance data in real-time, predicting potential failures to enable proactive maintenance, reducing costly downtime.

Quality Control: AI-powered vision systems scan bound books for defects, misalignments, or color inconsistencies with incredible accuracy and speed, identifying issues early to prevent waste.

Workflow Optimization: AI algorithms analyze production schedules, material availability, and machine capacity to determine the most efficient sequence for binding jobs, optimizing throughput.

3. On-Demand Binding and Personalization Technologies

The ability to produce unique or small batches of custom books is transforming publishing:

Digital Integration for Variable Data: Direct integration with digital presses allows for truly personalized books where covers, content, and spine text can vary from one book to the next in a single run.

Flexible Adhesive Systems (e.g., PUR Hot Melt): Advancements in adhesives like PUR (Polyurethane Reactive) offer stronger, more flexible bonds suitable for a wider range of paper types, including challenging digitally printed stocks. PUR also enables "lay-flat" binding and contributes to energy savings.

Modular Binding Solutions: Future systems will be highly modular and easily reconfigurable to handle diverse binding types (perfect bound, saddle stitch, wire-o, hardcover) and formats on the fly, catering to the varied needs of on-demand production.

4. Sustainable Bookbinding Innovations

The industry is making significant strides towards environmental responsibility:

Eco-Friendly Adhesives: Development of biodegradable, plant-based, and lower-VOC (volatile organic compound) adhesives reduces environmental impact.

Recycled and Sustainable Materials: Increased use of FSC-certified papers, recycled content, and natural fibers for book components is becoming standard.

Energy-Efficient Machinery: New equipment is designed to consume less energy, with some facilities integrating renewable energy sources.

Waste Reduction: Automation and precise material handling, guided by AI, inherently lead to less material waste through optimized cutting and more accurate glue application.

The Future of Bookbinding is Boundless

The future of technology in bookbinding is not about replacing the allure of the physical book, but enhancing its production to meet modern demands. It is about leveraging smart technologies to make the process faster, more efficient, more customizable, and more environmentally conscious. This means greater agility for publishers, optimized operations for printers, and the continued availability of high-quality, beautifully bound books for readers in an ever-evolving world.